Building Carbon Footprint

The AEC industry contributes significantly to the global warming. There are two types of carbon emissions: Embodied Carbon & Operational Carbon.

As nations and industries align their efforts to meet the goals of the Paris Agreement, targeting net-zero emissions by 2050, the AEC sector faces the dual challenge of addressing both embodied carbon and operational carbon.

Understanding the distinction between these two types of carbon emissions is essential for developing strategies that can lead to more sustainable construction practices and ultimately help mitigate climate change.

Paris 2050 Agreement: Summary

The Paris Agreement, adopted in 2015, established a global framework to limit global warming to well below 2°C, ideally aiming for 1.5°C, above pre-industrial levels.

This international treaty covers climate change mitigation, adaptation, and finance. Many countries and industries, including the AEC sector, have committed to reaching net-zero emissions by 2050.

This ambitious goal requires reducing both embodied and operational carbon emissions through innovative practices, materials, and technologies.

The lower the temperature increase, the smaller the effects of climate change can be expected. To achieve this aim, we must reduce greenhouse gas emissions as soon as and by as much as possible.

THE AIMS OF THE AGREEMENT

Holding the global average temperature increase to well below 2 °C above pre-industrial levels and pursuing efforts to limit the temperature increase to 1.5 °C above pre-industrial levels.

Increasing the ability to adapt to the adverse impacts of climate change and foster climate resilience and low greenhouse gas emissions development.

Making finance flows consistent with a pathway towards low greenhouse gas emissions and climate-resilient development.

Carbon Emissions: Big challenges for the future

For the global energy transition, electricity use will roughly double from today’s levels by 2050, meeting a majority of our energy needs across all three major sectors: Transportation, Industry, and Buildings & Infrastructure.

Half of all transportation will be powered by electricity, with hydrogen and other renewable fuels replacing petroleum products.

The industry will double its electricity use, meeting more than one-third of heating and process-energy requirements in addition to other renewable fuels.

Buildings & infrastructure will also double electricity use, with more than one-third of heating needs met by geothermal, biomass, and solar heat sources.

Coal will rapidly diminish, followed by a gradual phaseout of oil & gas, while renewables will expand from approximately 20% today to 100% in 2050.

Solar and wind power will meet 75% of electricity demand by 2050.

Renewable fuels and energy efficiency will significantly reduce overall consumption, driven by smart-grid transmission, more efficient appliances, better transportation logistics, and other measures.

In addition to a rapid phaseout of carbon emissions from deforestation, there is considerable potential for carbon dioxide removal through three restoration pathways: Natural forest restoration, combined with reforestation on 350 million hectares of degraded land, alongside sustainable forestry practices, can deliver 480 billion tonnes of carbon dioxide removal by 2100.

It is a significant effort to protect and restore natural ecosystems, which are the carbon sinks that keep our global climate system in balance.

STEPS TO ACHIEVING NET ZERO IN THE AEC INDUSTRY

Low-Carbon materials: The development and use of low-carbon and recycled materials, such as sustainably sourced timber, rammed earth, or adobe soil, can significantly reduce embodied carbon;

Circular economy approaches: Reusing and recycling materials from existing buildings, designing for deconstruction, and implementing modular construction methods can lower embodied emissions by minimizing the need for new materials;

Energy-efficient design: Incorporating passive design strategies, such as natural ventilation, daylighting, and thermal mass, can reduce operational carbon by minimizing artificial heating and cooling;

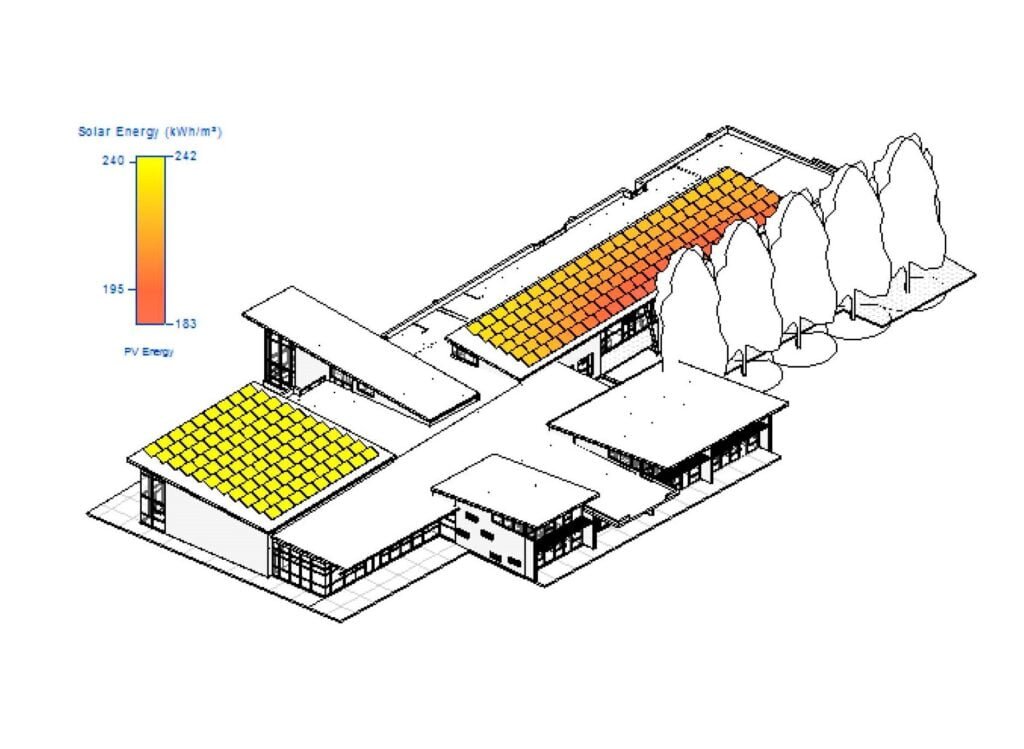

Renewable energy integration: Powering buildings with renewable energy, whether through on-site generation (solar, wind) or through the grid, is essential to reducing operational carbon;

Lifecycle assessments (LCA): By conducting LCAs during the design phase, architects and engineers can better understand and minimize the carbon footprint of their projects across their entire lifespan.

Embodied Carbon vs. Operational Carbon

Regarding the AEC industry, operational carbon is more evident in the short term. Still, embodied carbon is more important in the long term because the impact is much more significant when multiple actors are involved.

Traditionally, the AEC industry has focused on reducing operational carbon, mainly by designing energy-efficient buildings. This includes efforts to meet or exceed building energy codes, adopting renewable energy systems like solar panels, and using smart technologies to optimize energy use.

However, as buildings have become more energy-efficient, the relative importance of embodied carbon has grown. Today, up to 50% of the lifetime carbon emissions of a building could come from embodied carbon, especially in new, energy-efficient buildings.

As a result, reducing embodied carbon is now recognized as an urgent priority for the AEC industry. While operational carbon can be reduced over time through retrofitting, upgrading systems, or improving building performance, embodied carbon is locked in at the moment of construction.

Early design choices, such as material selection, sourcing, and construction methods, are critical for reducing the overall building footprint.

What is Embodied Carbon?

Embodied carbon refers to the greenhouse gas emissions associated with the entire lifecycle of a building’s materials, from extraction, production, and transportation to installation, maintenance, and disposal.

These emissions are “embedded” in the materials and processes required to construct buildings and infrastructure.

KEY SOURCES OF EMBODIED CARBON

Material extraction and manufacturing: This includes mining raw materials (such as limestone for cement or iron ore for steel) and the energy-intensive processes required to turn these materials into construction products. Cement production alone is responsible for roughly 8% of global carbon emissions.

Regarding the point above, EPDs (Environmental Product Declaration) are critical when discussing embodied carbon. They provide valuable data on the carbon emissions associated with manufacturing, enabling you to assess suppliers and select the most sustainable option.

Transportation: The carbon footprint involved in transporting building materials to construction sites, which can vary depending on distance and mode of transportation.

Construction activities: Using heavy machinery, construction equipment, and temporary infrastructure can significantly add to a project’s carbon emissions.

End-of-Life disposal: When a building is demolished, the disposal or recycling of materials generates additional emissions.

What is Operational Carbon?

Operational carbon, on the other hand, refers to the emissions produced by the energy consumption of a building during its use phase. It is directly tied to the building’s energy performance and reliance on fossil fuels or renewable energy sources.

This includes the heating, cooling, lighting, and ventilation of buildings and the energy required to power appliances and equipment.

KEY CONTRIBUTORS TO OPERATIONAL CARBON

Heating, Ventilation, and Air Conditioning (HVAC): These systems often consume the most energy in a building, especially in climates that require significant heating or cooling.

Lighting: While energy-efficient lighting can help reduce operational carbon, older buildings with outdated systems often have a much larger carbon footprint.

Building design and insulation: Poorly designed buildings with inadequate insulation require more energy to maintain comfortable indoor temperatures, leading to higher operational carbon.

Conclusions

Carbon is a critical KPI for the AEC industry, especially given its significant emissions. As we move toward 2050, the AEC industry must focus on reducing both embodied and operational carbon to meet the global climate goals set by the Paris Agreement.

AEC software should include carbon data from design to procurement to help industry professionals make informed decisions at every project stage.

By doing this, architects can see the carbon impact of their design choices in the early stages of a project. Integrating carbon data into design tools allows for flexibility and informed decision-making, helping to create low-carbon buildings from the outset.

Carbon tracking tools like Autodesk Insight and One Click LCA are necessary for creating more sustainable buildings. However, as AEC professionals, we must prioritize their deeper integration into our workflows to fully leverage their potential.

Furthermore, embedding carbon metrics into daily decision-making processes can effectively reduce emissions.

Achieving net-zero emissions in the built environment will require a holistic approach, including adopting sustainable materials, energy-efficient design, and integrating renewable energy systems.

The time to act is now, and the choices we make today in how we build our buildings, cities, and infrastructure will determine whether we can curb climate change for future generations.